Chemistry of Glass

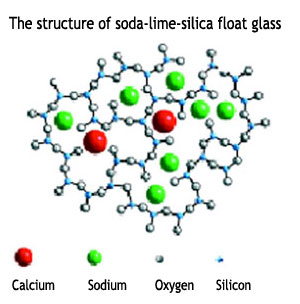

The main constituent of Flat Glass is SiO2 (silica sand). This has a high melting temperature in the region of 1700 degrees C and its state at this temperature is like syrup on a very cold day. The basic building block of silica has a tetrahedral pyramid shape with silicon at its centre linked symmetrically to four oxygen atoms at its corners: it has the chemical formula SiO4 and is negatively charged.

On cooling molten silica quickly, a random organised network of these tetrahedra are formed, linked at their corners, to give an amorphous material known as vitreous silica.

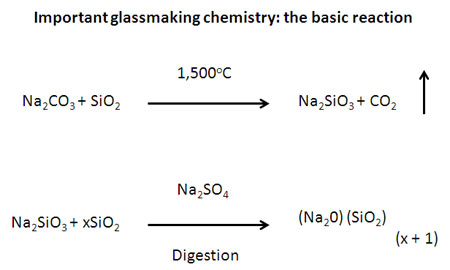

For practical and economic reasons, the high melting point and viscosity of silica is reduced by adding sodium oxide (a flux) in the form of a carbonate and the sodium-oxygen atoms enter the silicon-oxygen network, in accordance with their valency states. These atoms are known as Network Formers. Other major constituents of Flat Glass: Calcium and Magnesium enter the network structure as Network Modifiers and the action of these modifiers is to make the structures more complex so that when the components are melted together, in the cooling process, it is more difficult for the atoms to arrange themselves in suitable configurations for crystallisation to occur. In the glass making process, the cooling rate is arranged such that viscosity increases and the mobility of the atoms is hindered thus preventing arrangements and crystallisation from occurring.

Thus glass is often referred to as a supercooled liquid in that it has no crystallisation or melting point and does not exhibit the phenomenon of the latent heat of crystallisation or fusion.